Stone Cladding Installation Guide

1. Product Overview:

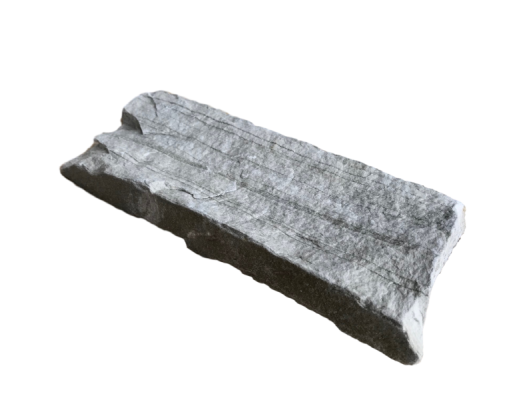

McMonagle Stoneer is a 100% natural stone cladding system, cut to 30mm thickness to give the exact look of “full thickness” stone. Suitable for interior and exterior projects, McMonagle Stoneer is light and easy to install, saving you valuable time, space and money. Available in a broad range of colours and materials like Donegal Quartzite, Sandstone, Slate and Limestone. L shaped corners and flat pieces are sold in boxes allowing for quick and easy delivery directly to your home.

2. Estimating Materials:

Flats

To estimate the number of flats you need simply multiply the height x width of the area to be covered. Then subtract any openings such as doors and windows. This is the total surface area for which you will need flat stone. Flats are sold per sq.m (m2).

Corners

To estimate how many corners you will need simply measure the vertical external corners i.e. the window and door jambs that will require corner stone. Please note that it is advisable to allow some extra time for cutting and trimming. Corners are sold by the metre.

Mortar

We recommend Ardex Adhesive X7G Plus, which has significantly less powder required per sq.m compared to traditional adhesives. To determine the quantity of mortar needed, allow one bag per 3 sq.m of flat stone. Multiply the total linear length of corners by 0.2 to give you additional bags required for corner stone. Please note additional mortar may be required depending on the stone type and quantity.

3. Preparation of the surface:

New Block Surfaces

No surface preparation is required for new block surfaces. We would recommend applying a scratch coat with a water sealer for chimney stacks to minimise water penetration.

Existing Surfaces

Existing plastered or dashed surfaces must be cleaned back to its original surface by sandblasting, water blasting, acid etching or wire brushing. Alternatively a metal lath could be attached using corrosive resistant concrete nails with a scratch coat applied over the metal lath.

Uneven / Rough Surfaces

For any uneven or rough surface, it is recommended to scratch coat to level the surface.

4. Installation:

Step 1 - Pre Application

-

Before applying, layout a couple of boxes in front of your project area to give yourself a sense for the variety of shapes and colours.

-

Arrange the pieces so they fit and look complimentary next to one another.

-

Try to avoid clumping colours together in the one area.

Step 2 - Install Corners First

-

Start at the corners and work towards the centre of the wall.

-

Be sure to alternate long and short returns on corner pieces.

-

Take a clean stone and slightly dampen the back, this will remove any dirt and will prevent moisture loss from mortar.

-

Apply a coat of mortar approx 10mm to the entire back of the flats and corners.

-

Press the stone onto the wall rotating slightly to force some of the mortar to squeeze out slightly.

-

Any mortar force out should be removed before the mortar is allowed to set. Mortar joints are better off narrow but should be consistent.

-

Fill large gaps with small stones and evaluate your work as you go along.

-

Cut and trim the stones if you need particular size stones to fill the gaps.

Step 3 - Fitting Stones & Grouting Joints

-

Fill all the gaps between the stones with grout mortar and/or sand cement/Lime to slightly above the desired finish depth. The grout will tighten and seal up the area around the stone.

-

Let the grout dry until it is firm but not solid. You want to be able to push on it without leaving fingerprints, but don't let the grout dry too much or it will be very difficult to strike.

-

Strike the grout to achieve the desired finish look.

-

Use your striking stick to scrape along the joints until the grout has a clean, even look to it.

Step 4 - Sweeping the Stone

-

Finally, use your medium bristled brush to sweep the dust off the stone.

5. Watch Video:

For further guidance check out the below demostration clip featuring our Sales Director, Michael McMonagle and Sean Nolan of Nolan Stonemasonry.